|

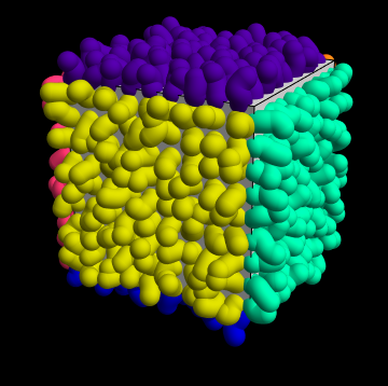

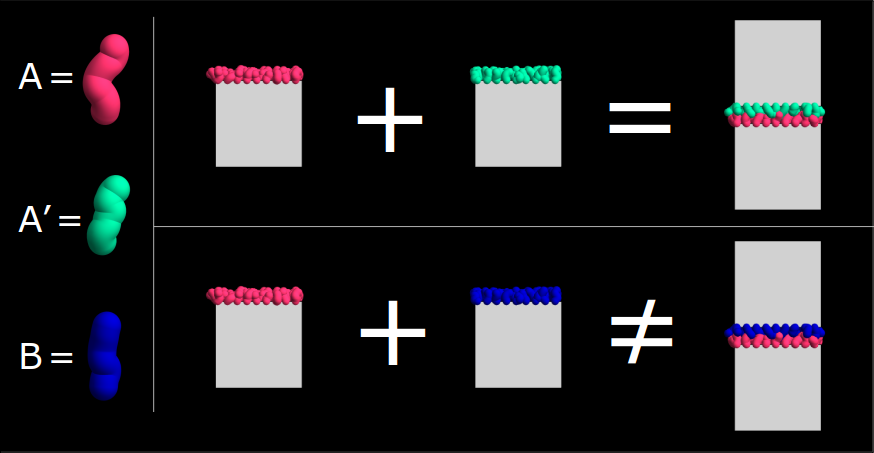

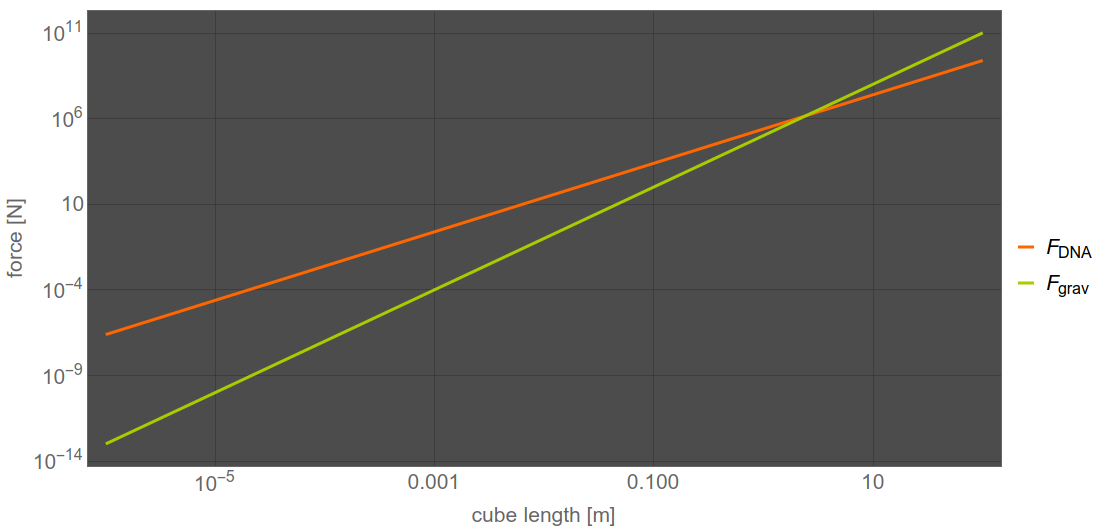

When you’re first exposed to nanotechnology, it can be difficult to grasp the immense difference in scale that nano-sized objects have. It’s helpful to think through the actual mechanics of how objects that size interact. For example, we use DNA linkers to bind DNP cubes together into useful structures. Just how strong are the bonds between DNA linkers? Imagine you’re playing a nano-sized version of the claw game, except instead of a mechanical claw, you’re going to lift objects with using DNA. It would look something like this: How large of a DNP cube could you lift? While there are many ways to bind nanoparticles together (e.g. covalent bonds, electrostatic attraction, hydrophilic/hydrophobic interactions, etc.), we typically use the stickiness of double stranded DNA. We do this by first painting single-stranded DNA on the cube's faces: When two cubes get close, they will bind together to form double stranded DNA, if and only if they have complementary sequences: Background. DNA is held together by hydrogen bonds and stacking interactions. At least a couple sources list the binding force of DNA as being in the piconewton (pN) range [1]. Let’s assume the force required to break apart one of the short DNA strands holding the cubes together is 4 pN. The total force holding the cubes together should be proportional to the number of DNA strands connecting them. If you have 2 DNA strands binding the cubes together, it should take 8 pN of force to break them apart. If you have 3 DNA strands, it should take 12 pN. If 10 DNA strands, it should take 40 pN. The more DNA strands you have, the stronger the cubes will bind together. How many DNA strands can you fit on the face of a cube? Clearly it depends on the size of the cube. Suppose you have a cube of length 10 nanometers (nm). The area of a single cube face would be 10 nm × 10 nm = 100 square nanometers. DNA is 2 nm wide, giving it a cross-sectional area of roughly 2 nm × 2 nm = 4 square nanometers [2]. Assuming you cover the surface of the 10 nm cube completely, we should be able to fit roughly 25 DNA strands onto a single face. How big is the force that binds cubes together? Since DNA has a force of 4 pN per strand and a 10 nm cube can fit 25 DNA strands on each face, the total force binding the cubes together will be 4 pN per strand × 25 strands = 100 pN. What if we use a larger cube? We can repeat the analysis above to estimate the maximum number of DNA strands that can fit on a cube face is number of strands ≈ (cube length in nm) × (cube length in nm) / 4 Using this formula, we can see that a 20 nm cube can fit 100 DNA strands, a 100 nm cube can fit 2500 DNA strands, a 1000 nm cube can fit 250,000 DNA strands, etc. If each strand delivers 4 pN of binding force, than the total force holding the cubes together is given by the equation total force in piconewtons ≈ (cube length in nm) × (cube length in nm) How much does the cube weigh? In order to lift an object, you need to overcome its weight, or in physics-speak, the gravitational force pulling it down. The force of gravity pulling the cube down is equal to its mass multiplied by the acceleration of gravity, which is roughly 9.8 meters per second squared. We can calculate the cube’s mass by multiplying its density times its volume. The volume is simply the length cubed. We’ll assume the nanocube is made of silver, which has a bulk density of 10.5 grams per cubic centimeter. Combining these facts, we can write the equation weight in grams = (0.000 000 000 10) × (length in nm) × (length in nm) × (length in nm), Notice that the particle’s weight is proportional to its length cubed, whereas the binding force is only proportional to the its length squared. This means that as the cube grows in size, the gravitational force pulling it down grows faster than the force of the DNA pulling it up. Eventually, the weight of the cube will be too much, and the DNA strands will not be strong enough to lift it. At that point, the DNA strands will break, and the cube will fall. We can see that on a plot of force versus cube length: We see that the gravitational force acting on the cube (green) grows faster than the DNA binding force (orange). The forces intersect at a cube length of approximately 2.4 meters. That’s an 8 foot long cube weighing 165 tons! Evidently, DNA is very strong if you have enough of them.

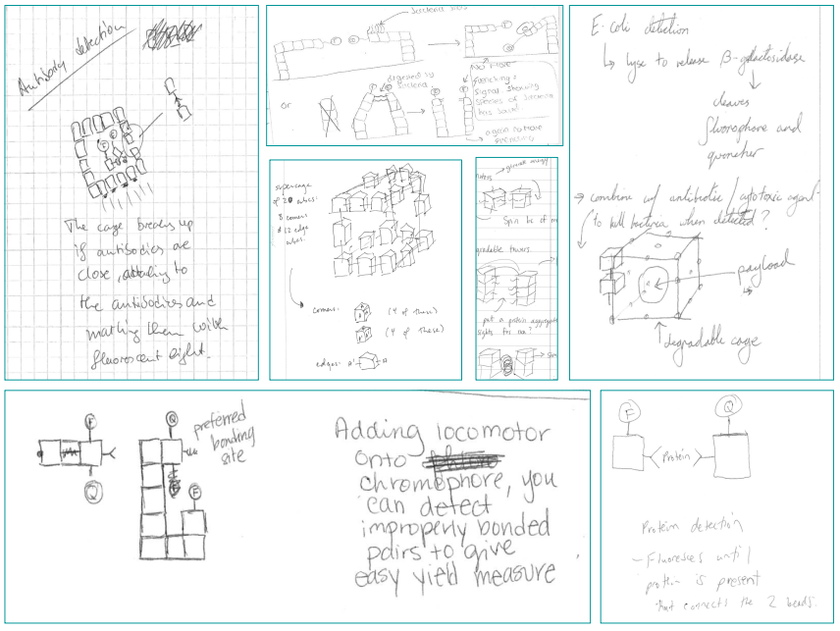

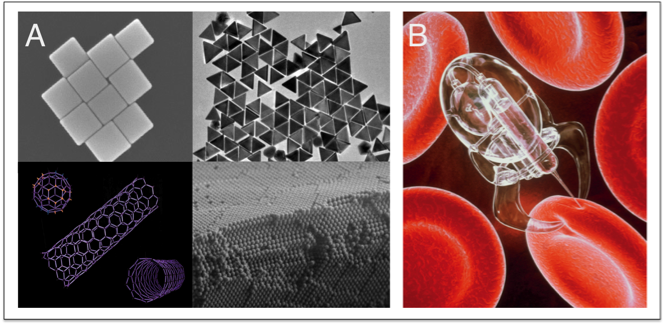

I should point out that for a real cube, the largest size that DNA can lift is almost certainly smaller than the result computed here. Nanocube faces are very flat, whereas bulk silver is rough and bumpy. When you stack bumpy cubes on top of each other, the bumps that stick out will be in contact with the other cube, but the dimples won’t be in contact with the other cube. Since the bumps and dimples will be larger than the short DNA strands, the strands located in the dimples will never reach far enough to bind with the DNA on the other cube. [1] A piconewton is 0.000 000 000 001 newtons of force. For example, see Phys.org’s “Measuring forces in the DNA molecule” or PicoTwist’s “Forces involved at the biological level”. [2] The cross-sectional area of DNA is more accurately described as a circle, but for an order of magnitude estimation such as this, the difference between the area of a square and the area of a circle will not be significant. A colleague recently asked "What can you build out of DNP cubes that you can't build out of spheres?" We've always had a difficult time answering this question succinctly. Rather than answer in words, we're going to actually show you...by running a nanotech design contest! You: Hey! What do you mean by "nanotech design contest"? DNP: We want you to design a solution to a real-world problem using nanotech. We'll see who can come up with the best solution to a given problem. You: How will the contest work? DNP: It will run like a hackathon, except instead of programming, you'll be designing nanotech devices. We'll start at 9a EST on a Monday, November 11, 2019 and run through 11:59p EST the following Sunday, November 17, 2019. Prior to 9a on Monday, we'll email you a packet of materials including a description of a real-world problem that should be solvable with nanotech. Then you get to (1) design a nanotech solution on paper, (2) describe your solution in three pages or less, and (3) enter your three-page write-up for a chance to win. You: Have you done anything like this before? DNP: Not formally. However, while presenting our work at the University of Michigan, we did have the audience design "some cool nanotech device" using DNP cubes. In only 5 minutes, they were able to come up with a wide variety of protein detectors, drug delivery schemes, and other cool nano devices: Fig. Sample nanotech designs created by audience members. You: Who can enter? DNP: Any team of 2-5 people. We're recruiting teachers and students, but anyone is welcome to enter. You: Why should I enter? DNP: Because it’ll be fun, and you want to solve big problems that will change the world! You: Great! Where do I sign up? DNP: There's an entry form below. To enter, gather 2-5 friends and form a team. Designate someone as the primary contact. (The primary contact is responsible for sending/receiving info for the contest.) Enter the primary contact's name, the email address where you'd like us to send contest info, and the names of all additional team members. You: Anything else I should know? DNP: To help you prepare, I'll make a few posts on this blog explaining the physics behind different nanotechnologies. This should help you prepare for the contest. Interested in designing nanotech devices? Sign up today! Best, Santos Consider the figure above. If you wish to synthesize any of the shapes shown on the left (Fig. A), you will find a variety of methods that suit your needs. Researchers have grown adept at synthesizing nanospheres, nanocubes, nanoprisms, nanotubes, lattices of nanoparticles, and a multitude of other highly symmetric monodisperse systems of nearly identical particles. However, if you instead wish to synthesize the object on the right (Fig. B), you will find currently available synthesis techniques extremely lacking. In the time since Richard Feynman first predicted the coming age of nanotechnology, popular science writers have promoted future advances with images of remote-controlled nanobots piloted through our blood streams, lancing our cancer cells, and keeping us healthy well into old age. Today, nanobots (and many other useful devices) can be conceived and designed theoretically, but they simply cannot be manufactured using tools currently available. While we have lathes, 3D printers, and a variety of other shape molding methods to create complex shapes at macroscale, there is presently no all-purpose “3D printer” equivalent manufacturing tool that can create a complete set of all shapes at nanoscale. Until we develop such a tool, the nanobot dream scenario will be relegated to the realm of science fiction. At DNP123, we are bridging the gap between design and assembly. This is possible because our patent-pending core IP—patched nanocubes that can be programmed to assemble any designable shape—affords a simple, standardized method of creating any structure at nanoscale. This assembly method permits the modular connection of device components, allowing complex products to be programmatically designed and assembled simply, quickly, and easily. What’s new in your approach? Why is it advantageous? At its core, our innovation is simply the ability to connect blocks. Its strength lies in simplicity and customizability: assembling complex new structures is just like building with LEGOs. Using DNA-patches on each face, we are able to program how nanocube blocks will bind to each other. The ability to connect blocks provides a general method for scaling up to complex three-dimensional structures in any desired shape, regardless how anisotropic or complex the target structure may be. Furthermore, the blocks self-assemble. This makes automating manufacturing particularly easy, since one need not use complicated robotic machinery in the assembly process. What impact will it make? From drug delivery containers to chemical sensors that detect bioterrorism, there is broad societal need for a standardized manufacturing platform that can assemble nanoscale products. A fast, inexpensive method of rapidly prototyping nanoscale products will extend nano- and biotech innovation beyond high priced research labs into early stage startups and college dorm rooms. The simplicity of our design-and-connect methodology makes it so that anyone with an imagination and the desire to invent can manufacture the next world changing nanotech device. Makers building with our technology can generate an explosion of products and innovation that one company alone could never hope to produce. What will it take to succeed? To be successful, DNP123 technologies needs an active base of dedicated users looking to build the next generation of nanoscale technologies. Are you an academic, governmental, or industrial researcher with a nanotech problem you’ve been unable to solve by conventional means? Are you a tinkerer looking for a new medium to play in? If so, we want to hear from you. Visit our Contact page and introduce yourself. We’ll work with you to get you up and running. The future is in your hands. What will you build? —Santos

|

RSS Feed

RSS Feed